|

|

|

The first step in making the top after

The first step in making the top after

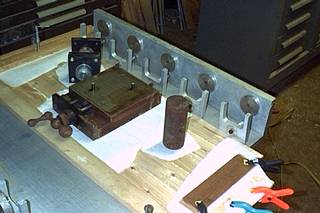

The next step is to glue the top pieces

together. To the left is a view of the

clamp system I found while wondering

around the local junk yard. It uses lock

clamps and is made of 1/2 inch thick

aluminum. To keep the pieces flat I've

used a few heavy objects in the shop.

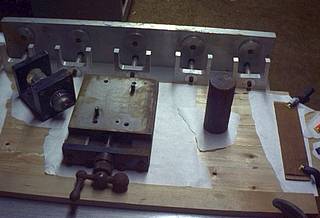

Here is another view of the clamp.

In the

future I would like to run some bars over the

top and place vertical clamps to take the

place of the weights.

Here is a view of the top after

being removed from

the clamp. The piece on the top left is just a

filler.

Lessons learned: Wood glue will stick to aluminum.

Next time I will put wax paper under it first.

The

clamp worked well but I will need to put the vertical

clamps in to hold the stock flat.

Here is a view of the top after being cut to rough

size and sanded. The average thickness is

.125.

Click here for

a close up view showing more detail.

And yes, some of those are worm holes.

The next step is to make the kerf

lining. Here is

a photo of a simple jig to do that. I used and

old

jig saw I had (broke handle) and made a simple

slide. The dept is controlled by the back stop.

Now it's time to glue the linings in place.

I sure

hope the wife doesn't need to do the wash. Cloths

pins make short work of this job and their cheap.

But the 50 cent spring clamps from wally world

are also nice. Will be getting more those.

Home Sides Top and bottom Fret board Tuning head